Creating the surface

After recording the high-resolution data of the Tomb of Seti I in 2001, Factum Foundation experimented with the process of rematerialising such high-resolution data in bas-relief. By 2016, after successfully creating facsimiles of the Burial Chambers of Thutmosis III and Tutankhamun, Factum Foundation perfected the process.

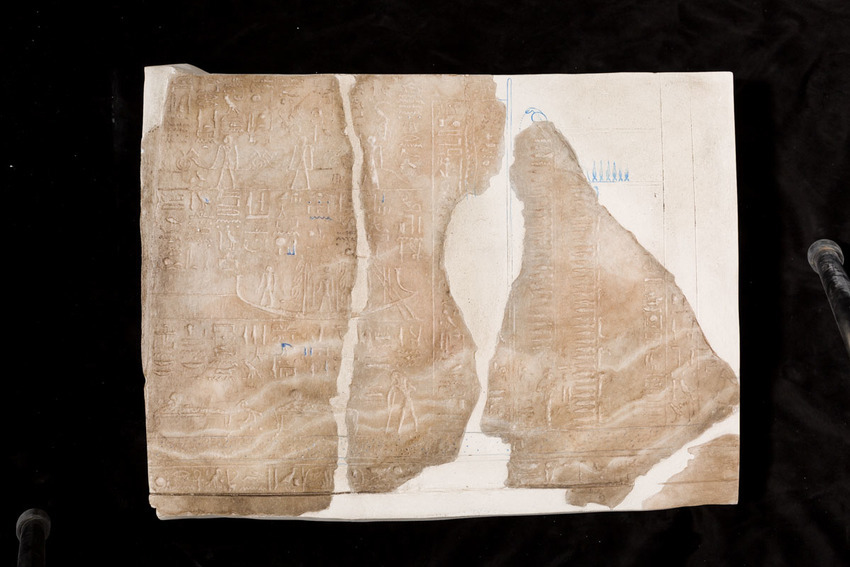

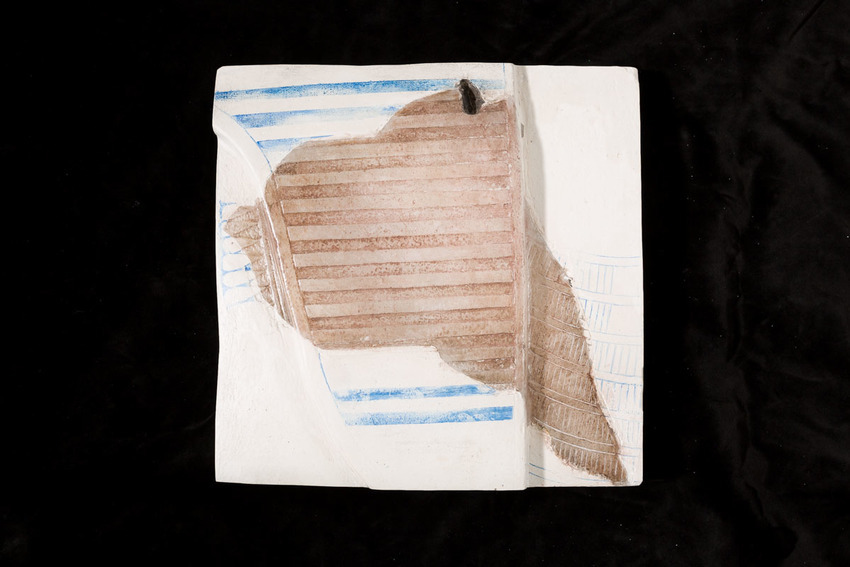

Two main processes were employed to recreate the complex surface of walls, ceilings, and pillars in the two rooms, based on the depth of the carvings and the level of detail required. For intricate bas-reliefs and irregular surfaces, the data was carved into polyurethane 1x2m boards using CNC milling. These boards were cut into irregularly shaped sections that could be transported and assembled with invisible joints.

© Oscar Parasiego | Factum Foundation

CNC-milling the surface © Oak Taylor-Smith | Factum Foundation

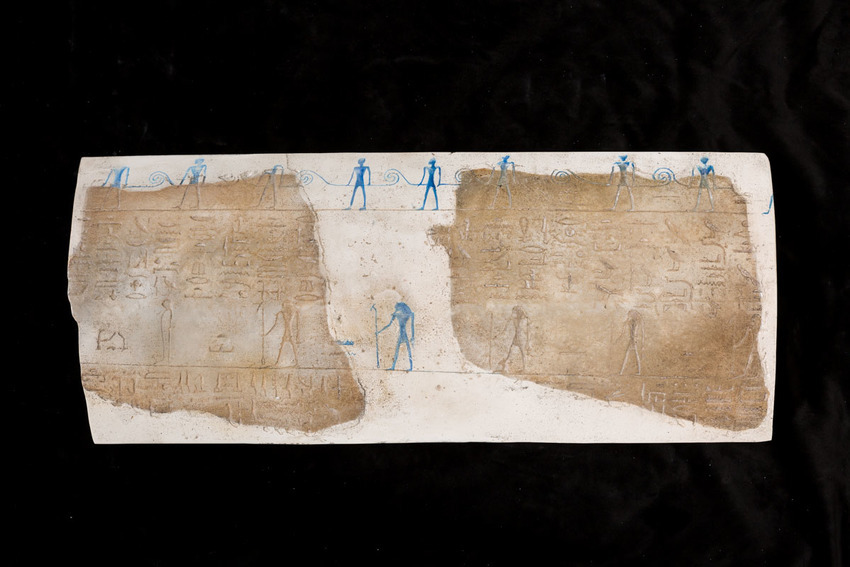

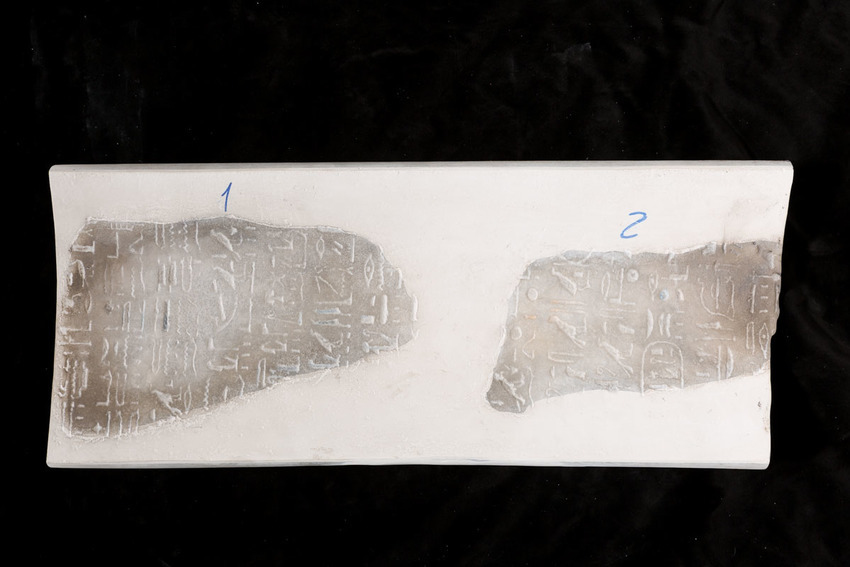

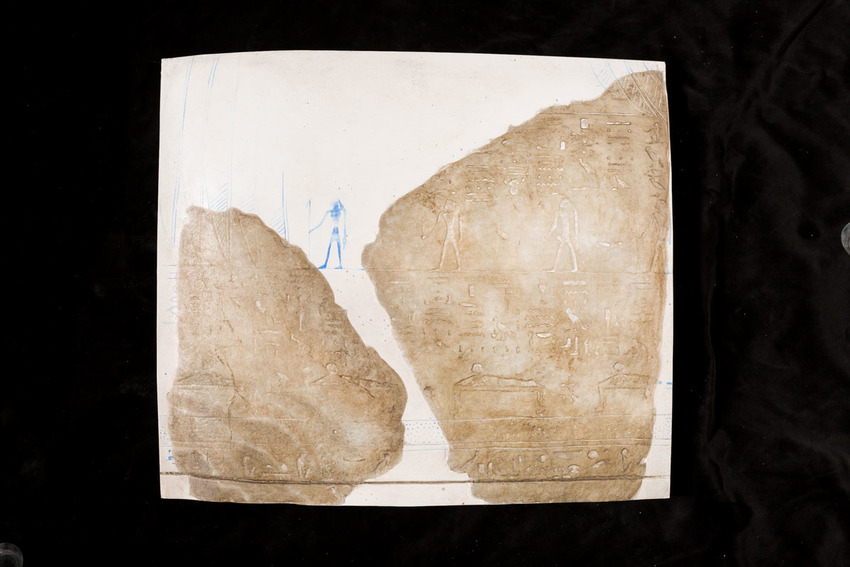

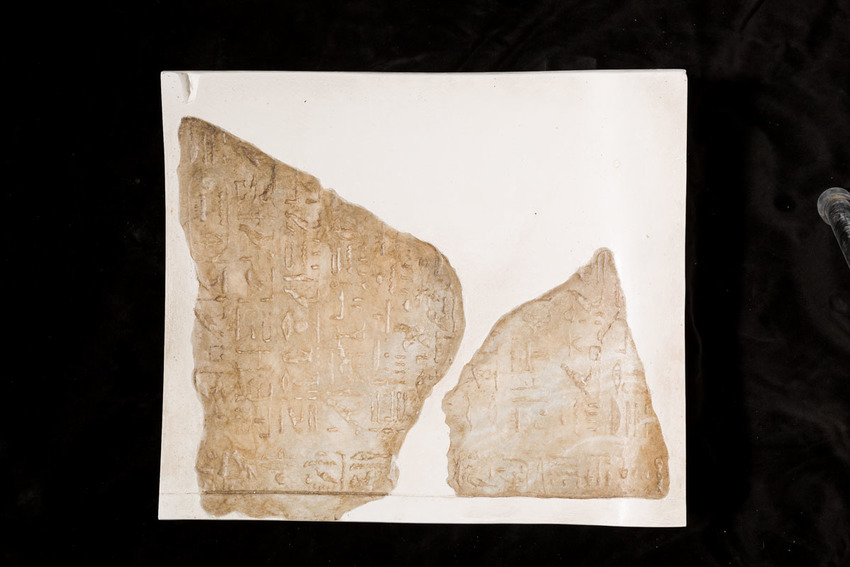

For finer surfaces, Factum Foundation and Canon Production Printing (previously known as Océ – A Canon Company) tested and improved elevated printing. Some of the reliefs exceeded the 5mm height limit of the textured prints produced through elevated printing at that time. To address this, Canon Production Printing’s research and development department created an experimental slicing algorithm and modified the print processes, achieving breakthroughs in the technology. Casts of the elevated prints were then made using traditional plaster-casting methods, reinforced with acrylic for a stiff surface.

A large moulded section (left) and its mould (right) © Factum Foundation

Applying the colour

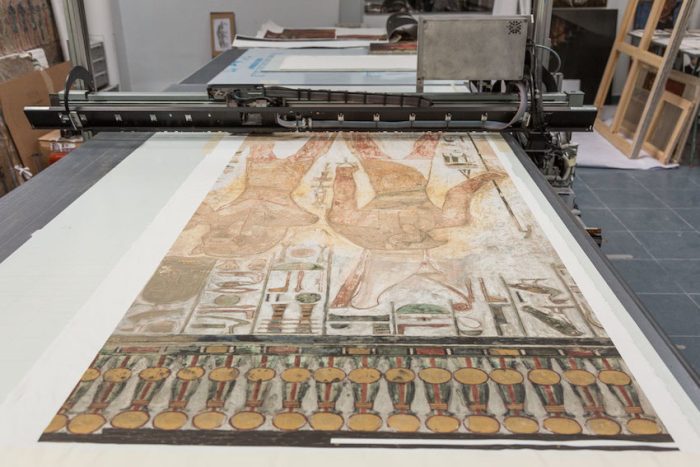

While Factum Arte’s flatbed digital printer can overprint multiple layers of colour in perfect register, a different approach was needed for the carved surfaces of the tomb. Similar to Tutankhamun’s Burial Chamber facsimile, the colour was printed onto elastic ‘skins’ that could be attached to the routed or cast relief surfaces. These specially prepared skins, developed by Factum Arte, consist of two thin layers of ink-jet ground backed with an acrylic gesso over an elastic, acrylic support. They are built in seven layers rolled onto a lightly textured silicon mould. As they have a short working life, they need to be made freshly to ensure they stretch and fit the surface correctly.

© Oscar Parasiego | Factum Foundation

The skins can be printed in sheets that are one and a half meters wide and up to three meters long, minimising the number of joints in the final facsimile. Positioning the skins required using a raking light, and Factum experts re-positioned them until all details in the print matched the underlying surface. The elastic support allowed for slight stretching of the surface to ensure a perfect fit. Defined registration points, like sharp angles of flaking paint, defined cracks, or edges of damaged areas, needed to be identified since the fit between the paint and the relief surface was not always obvious.

Once the skins were positioned and held in place with a slow-cure contact adhesive, they were placed into a vacuum bag with a polyester blanket. A vacuum pump applied uniform pressure, ensuring full contact and adhesion between the skin and the support. The skin’s elastic nature caused it to take on the character of the underlying relief, resulting in a surface where the colour and texture are fused together.

After being hand-retouched, the panels could be transported and assembled on-site.

Room I The Hall of Beauties

Room J

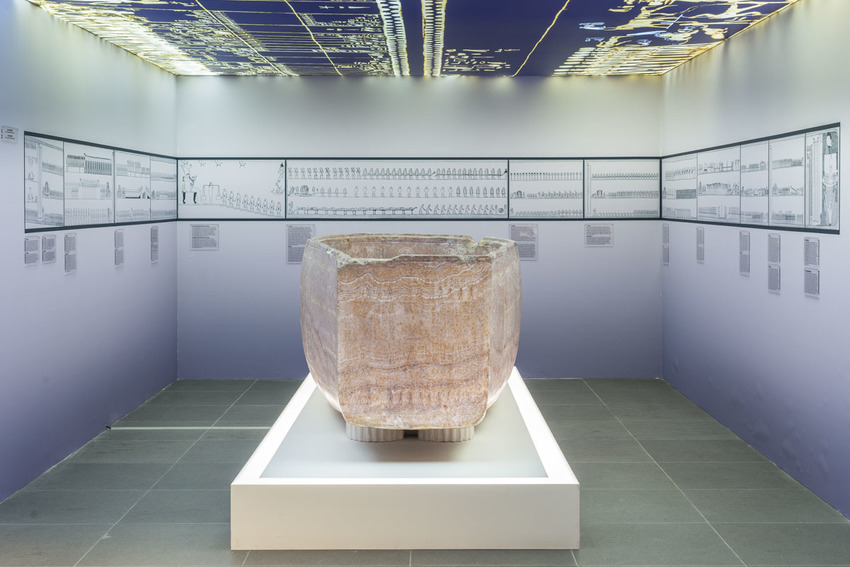

The Sarcophagus

The Lid

The Fragments

The Tomb Model

The LiDAR scan of the tomb was rematerialised so that visitors could ‘travel’ through the entire building as they entered the exhibition.